Audits & Troubleshooting

Comprehensive Heat Trace System Audits

FTS Industrial Services provides comprehensive heat trace system audits to assess overall performance and identify opportunities for improving energy utilization, minimizing heat loss, and reducing costs. Our heat trace audits enable us to isolate and repair issues and identify costs related to system design, installation, corrosion, leaks, and more. The primary objective of an audit is to increase the system’s lifespan, reduce downtime, and decrease maintenance costs.

Heat Trace System Audit Includes:

OUR HEAT TRACING AUDIT PROCESS

We collaborate with customers to assess their heat tracing systems, ensuring they meet operational requirements and surpass expectations. Our audit services entail conducting performance and efficiency audits on existing heat tracing systems.

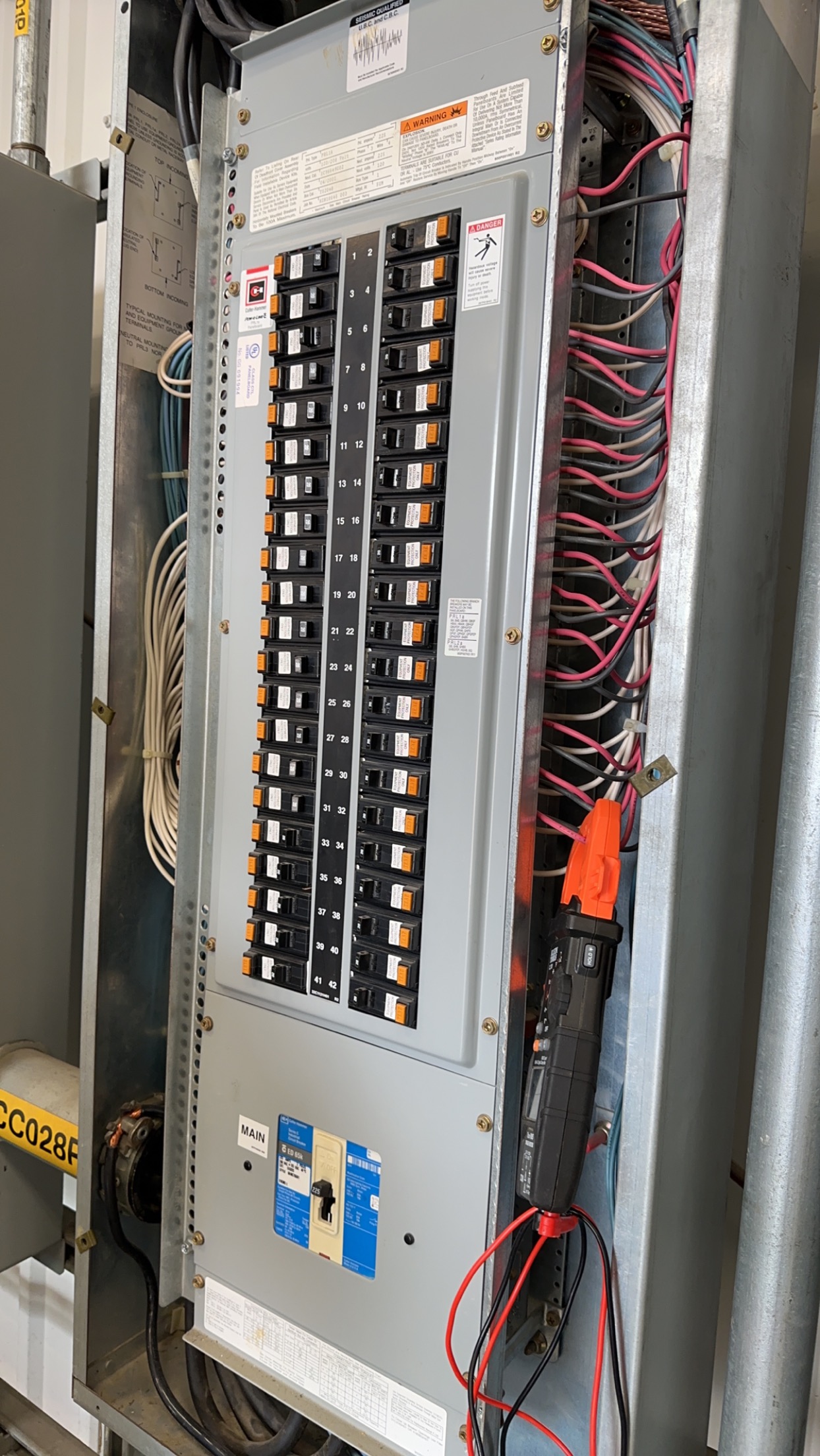

During our heat trace system audit, our technicians visually inspect the system’s insulation, heat tracing components, control panels, and other controls. We conduct electrical testing and inspect the heat tracing system’s components and cable. We also review the control system’s process set points and temperature, circuit current and voltage, and ground fault status, among other aspects. Additionally, we perform minor troubleshooting to determine if a circuit can be recovered without additional repair work.

Upon completion of the inspection, testing, and troubleshooting, we provide a comprehensive evaluation of the systems and recommend corrective actions. Customers receive a detailed report highlighting the system’s current state and presenting optimization options and system upgrades to enhance overall performance.